PIXUS ATCA SHELF, 13U

Description

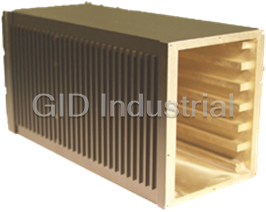

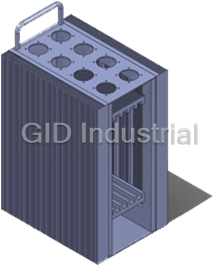

The 13U ATCA shelf design has over 15,000 global installs. This superior chassis design has been adopted by leading companies worldwide. It features a 14-slot backplane in 10G or 40G versions. With higher speeds, EMC protection is more critical than ever. The Pixus shelf offers a patented EMC mat below the card cage. This design solution helps EMC without degrading airflow.

Part Number

ATCA SHELF, 13U

Price

Request Quote

Manufacturer

PIXUS

Lead Time

Request Quote

Category

Uncategorized

Specifications

Size

19" x 13U x 385 mm depth

Features

- Plug & play-compatible for ShMC, Intel WT or PP 500

- Hot swap-compatible, redundant fans for cooling of min. 200 W/board

- System monitoring using Shelf Management Controllers (ShMC)

- Conforms to PICMG 3.0 rev. 2.0

- Fully assembled, wired and function tested

Datasheet

Extracted Text

Section 1_2-51 4/7/04 9:18 AM Page 17 Order Information ■ ® AdvancedTCA Shelf Basic Mechanical Elements: The Subrack: The basic elements of the platform are: ■ The Subrack provides for the Front Board and optional RTM interfaces. The Boards: ■ The 14 slot or the 16 slot subrack ■ A mix of IEC 60297-3 dimensions provides for attachment points and PICMG 3.0 specific mechanical of the backplane, as well as solutions. alignment/keying, support and mechanical advantage of the ■ Front Boards (8U x 6HP and insertion and extraction of Front 280 mm depth) contain the Boards and optional RTM’s. electronic functions and the required connectors. The PCB is offset to the ■ The Subrack provides for the pitch-line by 6.61 mm and may be optional Zone 3 I/O and the A/K2 1.6 mm to 2.4 mm of nominal alignment/keying interface. thickness and includes a component The Shelf: side 1 ESD strip and component side 2 cover attachment holes. ■ The Shelf consists of the integrated The Front Board assembly includes, Subrack, Cooling/Filter Devices, as mandatory features, a Front Power Entry Modules, System Panel assembly with Alignment/ Management Functions and Cable GND Pin, EMC Gasket, ESD strip, Management Injector/Extractor/Locking handles ■ The Shelf may support either 14 with optional microswitch operation slots or 16 slots (for 16 slots inquire) for Hot-Swap and optional M3 ■ The 14 slot Shelf may be 19" based retention screws. A component side or ETSI based (for ETSI inquire) 2 (backside) cover is for PCB stiffening and/or EMI protection ■ The 16 slot Shelf may be 23" based is mandatory. or ETSI based (please inquire) The Connectors: ■ The height of the Shelf may be N x U (19"/23") or N x 25 mm (ETSI) ■ Zone 1: Power and System Management. ■ The depth of the Shelf is approxi- mately 390 mm to fit into a 600 mm Zone 2: Data Transport. deep cabinet Zone 3: Rear I/O. Zone 1 and Zone 2 are controlled by a dedicated Alignment/Keying Device. Optional, additional Zone 3 applications provide for AdvancedTCA is a registered trademark of a further dedicated Alignment/ ® PICMG Rittal Corporation reserves the right to Keying device. improve, alter or cancel any of its product line. 16 Section 1_2-51 4/7/04 9:18 AM Page 18 Order Information ■ ® AdvancedTCA Shelf ■ Vertical 13U - Cooling Vertical 13U - Shelf Management Shelf Cooling Features: Management interfaces throughout the Shelf enable the monitor & control of: ■ Designed to cool 200 Watts/Slot ■ Boards ■ Rear Baffles prevent hot air re-circulation. ■ PEM (Input/Output Voltages & Current) ■ RTM is cooled by vacuum effect. (Approximately 30 Watts/Slot) ■ Blowers ■ Field replaceable dust filter located ■ Air inlet temperature below lower card guide assembly. ■ Remote alarm signals ■ Air filter present sensor The AdvancedTCA Developer Chassis The 13U x 14 slot AdvancedTCA Developer Chassis is designed to comply with the electronic requirements of PICMG 3.0 and provide developers with an open sided bench top. The AdvancedTCA platform to architect applications based on the PICMG 3.0 specification. The AdvancedTCA Developer Chassis accommodates 14 slots of 8U x 6 HP x 280 mm Front Boards and 8U x 6 HP x 70 mm RTM (Rear Transition Modules). The AdvancedTCA Developer Chassis is available with 14 slot Kaparel/Rittal Full Mesh or Dual-Star architecture backplane. The AdvancedTCA Developer Chassis is cooled by six 115 cfm – 48V DC fans and includes dual 48V DC input feeds and ESD socket. Order No. Height 14U Side panel No. of slots Usable width HP For front board For RTMs Quantity For 19 inch depth (mm) EIA 310-D/IEC60297-1 385 14 84 8U x 280 mm 8U x 70 mm 9808623 17 Section 1_2-51 4/7/04 9:18 AM Page 19 AdvancedTCA Shelf Version VA AdvancedTCA Shelf Version VB Front View Version VA Rear View Air Flow – Sec. Side View EMI Containment – Sec. Side View 18 Section 1_2-51 4/7/04 9:18 AM Page 20 Order Information ■ ® AdvancedTCA Shelf ■ AdvancedTCA Shelf Version VA-1 Description: Order No. Compliant with ShMC PC PEM Qty Shelf ■ 19" x 13U x 385 mm depth (base) (23"/ETSI x 13U/600 x 385 mm depth optional) Bussed IPMI 1 3688305 ■ 14 x 6HP slots for front boards and RTMs FCI Kernel x 1 optional ■ 14 slot full mesh backplane, bussed IPMI Kaparel/Kernel/PC 3688323 1 optional ■ 2x rear PEMs, redundant (4x optional) PEM-Basic 3688378 1 optional ■ Space for 2x rear mounted ShMC PEM-IPMI 3688388 1 optional ■ Space for 2x rear mounted peripheral controller ShMC: The choice of the backplane is based on the Shelf Management Controller (ShMC) used. ■ 1 x rear mounted auxilliary telephony panel The functionality of the chosen ShMC will define the functionality of the Peripheral Controller (PC). 3688305 is defined for Force Computers (FCI) ShMC rear mount requirements. ■ 4 x RiCool-2 blowers, dual IPMI, 180cfm/300m3/h PEM: There are various types of Power Entry Modules (PEM) available based on application needs. ■ 1 x front removable air-filter A min of 2 are required, a max of 4 postions are provided for. ■ Optional front and rear cable tray AdvancedTCA Shelf Version VB-1 Order No. Description: Compliant with ShMC PC PEM Qty Shelf ■ 19" x 13U x 385 mm depth (base) (23"/ETSI x 13U/600 x 385 mm depth optional) Radial IPMI 1 3688301 ■ 14 x 6HP slots for front boards and RTMs Intel CMM x 1 optional ■ 14 slot full mesh backplane, radial IPMI Kaparel/CMM/PC 3688322 1 optional ■ 2 x rear mounted PEMs (4x optional) PEM-Basic 3688378 1 optional ■ Space for 2x front mounted ShMC PEM-IPMI 3688388 1 optional ■ Space for 2x rear mounted peripheral controller ShMC: The choice of the backplane is based on the Shelf Management Controller (ShMC) used. ■ 1 x rear mounted auxilliary telephony panel The functionality of th chosen ShMC will define the functionality of the Peripheral Controller (PC). 3688301 is defined for Intel CMM requirements. ■ 4 x RiCool-2 blowers, dual IPMI, 180cfm/300m3/h PEM: There are various types of Power Entry Modules (PEM) available based on application needs. ■ 1 x front removable air-filter A min of 2 are required, a max of 4 postions are provided for. ■ Optional front and rear cable tray AdvancedTCA Shelf Version VB-2 Description: Order No. ■ 19" x 13U x 385 mm depth (base) Compliant with ShMC PC PEM Qty Shelf (23"/ETSI x 13U/600 x 385 mm depth optional) Bussed IPMI 1 3688302 ■ 14 x 6HP slots for front boards and RTMs PP ShMM 3688320 1 optional ■ 14 slot full mesh backplane, bussed IPMI Kaparel/ShMM/PC 3688324 1 optional ■ 2 x rear mounted PEMs (4x optional) PEM-Basic 3688378 1 optional ■ Space for 2x front mounted ShMC PEM-IPMI 3688388 1 optional ■ Space for 2x rear mounted peripheral controller ShMC: The choice of the backplane is based on the Shelf Management Controller (ShMC) used. ■ 1 x rear mounted auxilliary telephony panel The functionality of th chosen ShMC will define the functionality of the Peripheral Controller (PC). 3688302 is defined for Pigeon Point (PP) ShMM requirements. ■ 4 x RiCool-2 blowers, dual IPMI, 180cfm/300m3/h PEM: There are various types of Power Entry Modules (PEM) available based on application needs. ■ 1 x front removable air-filter A min of 2 are required, a max of 4 postions are provided for. ■ Optional front and rear cable tray AdvancedTCA Shelf Version VB-3 Description: Order No. ■ 19" x 13U x 385 mm depth (base) Compliant with ShMC PC PEM Qty Shelf (23"/ETSI x 13U/600 x 385 mm depth optional) Bussed IPMI 1 3688343 ■ 14 x 6HP slots for front boards and RTMs FCI Kernel x 1 optional ■ 14 slot full mesh backplane, bussed IPMI Kaparel/Kernel/PC 3688323 1 optional ■ 2 x rear mounted PEMs (4x optional) PEM-Basic 3688378 1 optional ■ Space for 2x front mounted ShMC PEM-IPMI 3688388 1 optional ■ Space for 2x rear mounted peripheral controller ShMC: The choice of the backplane is based on the Shelf Management Controller (ShMC) used. ■ 1 x rear mounted auxilliary telephony panel The functionality of th chosen ShMC will define the functionality of the Peripheral Controller (PC). 3688343 is defined for Force Computers (FCI) ShMC front mount requirements. ■ 4 x RiCool-2 blowers, dual IPMI, 180cfm/300m3/h PEM: There are various types of Power Entry Modules (PEM) available based on application needs. ■ 1 x front removable air-filter A min of 2 are required, a max of 4 postions are provided for. ■ Optional front and rear cable tray 19 Section 1_2-51 4/7/04 9:18 AM Page 21 Order Information ■ ® AdvancedTCA Backplanes AdvancedTCA Shelf Version HA-1 – Horizontal Description: Order No. Compliant with ShMC PC PEM Qty Shelf ■ 19" x 3U x 385 mm depth (base) Bussed IPMI 1 3688299 ■ 4 x 6HP slots for front boards and RTMs FCI Kernel x 1 optional ■ 4 slot full mesh backplane, bussed IPMI Kaparel/Kernel/PC on board 1 included ■ Redundant power entry on rear ■ Space for 2x rear mounted ShMC Note: The choice of the backplane is based on the Shelf Management Controller (ShMC) used. ■ Telco Alarming, rear The functionality of th chosen ShMC will define the functionality of the Peripheral Controller (PC). ■ Front removable fan tray, right side (2 fans) 3688299 is defined for Force Computers (FCI) ShMC front mount requirements. Front to back airflow is not achievable in the 19" format. ■ Front removable fan tray, left side (2 fans) ■ Front removable filter, right side ■ Airflow, right to left AdvancedTCA Shelf Accessories Accessories Description Used For Quantity Order No. Zone 3 air seal 6HP - FR4 Zone 3 1 3688290 Filler panel (FP) 8U x 6HP front/rear 1 3688266 FP w/air management 8U x 6HP x 280 mm front 1 3688267 FP w/air management 8U x 6HP x 70 mm rear (RTM) 1 3688268 Note: Due to the flexibility of the PICMG 3.0 Specification many ShMC solutions may emerge. The above shelf designs are based on sound mechanical research. The AdvancedTCA Backplanes: Kaparel/Rittal are active members of the PICMG 3.0 subcommittee including a contract for the simulation and routing analysis for the Dual Star, Dual-Dual Star and Full Mesh configurations. Simulations were run using a minimum speed of 3.125 Gbps. For the base and Fabric Interface, an 8 mil line width, 10 mils within the pair and 35 mils pair to pair achieving a low 0.2% noise coupling. Simulations were also run on 5 Gbps and above but showed that steps like back drilling and/or silicon equalization options may be required. Kaparel/Rittal offers a complete range of off-the-shelf 14 and 16 slot versions of their AdvancedTCA backplanes including Full Mesh, Dual Star, Dual-Dual Star and Dual Dual Stare with 1x Mesh overlay. In addition custom designs are available for specific customer applications. A 4 slot Full Mesh version will be available for horizontal chassis applications. The Dual Star version is completed in 14 layers and the Full Mesh in 36 layers, both in Nelco material. This material allows a thinner board as well as provides the signal integrity required for AdvancedTCA based applications. The backplanes use the high speed AMP/ERNI ZD connector in zone 2 for signal noise and ease of routing differential pairs. The routing uses broadside differential pairs providing low The 14 slot Full Mesh AdvancedTCA Backplane noise coupling without additional signal layers. Off-the-shelf or custom AdvancedTCA solutions available from Kaparel/Rittal will allow you to get your applications quickly to the market. The AdvancedTCA Backplanes Order No. Model No. Slots Description 3688760 10401 4 Full mesh bussed IPMI 3688763 11401 14 Full mesh bussed IPMI 3688307 11404 14 Dual Star bussed IPMI 3688317 11601 16 Full mesh bussed IPMI 3688429 11604 16 Dual Star bussed IPMI Note: Radial IPMI versions available, please contact the factory. Cool Running: Actual thermal image of Kaparel/Rittal 11401 backplane under full load conditions – 14 slots at 200W. The red imaging at top is feed through from load resistors. 20

Frequently asked questions

Why choose IPC Station?

What is IPC Station' warranty policy for the ATCA SHELF, 13U?

What carriers does IPC Station use to ship parts?

Does IPC Station sell to international (non-USA) customers?

What methods of payment does IPC Station accept?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Related Products

The Kaparel/Rittal 23000 Series of 3U PXI backplanes are PXI R2.0 and nPICMG 2.8 draft specification...

Due to its compact design, the 5 U shelf version offers optimum application possibilities, e.g. as a...

Due to its compact design, the 5 U shelf version offers optimum application possibilities, e.g. as a...

The Pixus Backplanes Division leverages designs from Kaparel, a leading innovator of AdvancedTCA des...

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods