PORTWELL LPCI-IIRO-8

Description

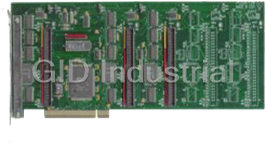

Half-size Low-Profile PCI bus compatible card that provides isolated digital input and output interface for PCI-Bus computers. The card has eight optically-isolated digital inputs for AC or DC control signals and eight electromechanical relay outputs.

Part Number

LPCI-IIRO-8

Price

Request Quote

Manufacturer

PORTWELL

Lead Time

Request Quote

Category

PCI Digital I/O Products

Specifications

Categorization Information

PCI Digital IO Products

Features

- High Speed USB 2.0 device, USB 1.1 compatible

- 8 optically-isolated, non-polarized CMOS compatible digital inputs accept volts DC or AC rms

- 8 form C electro-mechanical relays switch up to 1 A each

- Custom high-speed function driver

- Removable screw terminal adaptor for easy wiring

- Small, portable module (3.5 by 3.7 in.)

- Rugged industrial enclosure

- Universal PCI, PCI-X, 3.3V and 5V compatible

Datasheet

Extracted Text

C C C MODEL LPCI-IIRO-8 USER MANUAL FILE: MLPCI-IIRO-8.A1e Notice The information in this document is provided for reference only. Portwell does not assume any liability arising out of the application or use of the information or products described herein. This document may contain or reference information and products protected by copyrights or patents and does not convey any license under the patent rights of Portwell, nor the rights of others. IBM PC, PC/XT, and PC/AT are registered trademarks of the International Business Machines Corporation. Printed in USA. Copyright 2006 by Portwell I/O Products Inc. All rights reserved. WARNING!! ALWAYS CONNECT AND DISCONNECT YOUR FIELD CABLING WITH THE COMPUTER POWER OFF. ALWAYS TURN COMPUTER POWER OFF BEFORE INSTALLING A CARD. CONNECTING AND DISCONNECTING CABLES, OR INSTALLING CARDS INTO A SYSTEM WITH THE COMPUTER OR FIELD POWER ON MAY CAUSE DAMAGE TO THE I/O CARD AND WILL VOID ALL WARRANTIES, IMPLIED OR EXPRESSED. 2 Manual LPCI-IIRO-8 Warranty Prior to shipment, Portwell equipment is thoroughly inspected and tested to applicable specifications. However, sho uld equipment failure occu r, Portwell assu res its customers that prompt se rvice and sup port will be available. All equipment originally manufactured by Portwell which is found to be defective will be repaired or replaced subject to the following considerations. Terms and Conditions If a unit is suspected of failure, contact Portwell' Customer Service department. Be prepared to give the unit model number, serial number, and a description of the failure symptom(s). We may suggest some simple tests to confirm the failure. We will assign a Return Material Authorization (RMA) number which must appear on the outer label of the return package. All units/components should be properly packed for handling and returned with freight prepaid to the Portwell designated Service Center, and will be returned to the customer's/user's site freight prepaid and invoiced. Coverage First Three Years: Returned unit/part will be repaired and/or replaced at Portwell option with no charge for labor or parts not excluded by warranty. Warranty commences with equipment shipment. Following Years: Throughout your equipment's lifetime, Portwell stands ready to provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in the industry. Equipment Not Manufactured by Portwell Equipment provided but not manufactured by Portwell is warranted and will be repaired according to the terms and conditions of the respective equipment manufacturer's warranty. General Under this Warranty, liability of Portwell is limited to replacing, repairing or issuing credit (at Portwell discretion) for any products which are proved to be defective during the warranty period. In no case isPortwell liable for consequential or special damage arriving from use or misuse of our product. The customer is responsible for all charges caused by modifications or additions to Portwell equipment not approved in writing by Portwell or, if in Portwell opinion the equipment has been subjected to abnormal use. "Abnormal use" for purposes of this warranty is defined as any use to which the equipment is exposed other than that use specified or intended as evidenced by purchase or sales representation. Other than the above, no other warranty, expressed or implied, shall apply to any and all such equipment furnished or sold by Portwell. 3 Manual LPCI-IIRO-8 TABLE OF CONTENTS Chapter 1: Introduction ............ ............ ............ ............ ............ .... 5 Figure 1-1: Block Diagram ............ ............ ............ ............ 8 Chapter 2: Installation ............ ............ ............ ............ ............ .... 9 Chapter 3: Option Selection ............ ............ ............ ............ ........... 11 Figure 3-1: Option Selection Map ............ ............ ............ ...... 11 Chapter 4: Address Selection ............ ............ ............ ............ .......... 12 Chapter 5: Programming ............ ............ ............ ............ ............ . 13 Chapter 6: Connector Pin Assignments ............ ............ ............ ............ .. 14 Table 6-1: Connector Pin Assignments ............ ............ ............ . 14 4 Manual LPCI-IIRO-8 Chapter 1: Introduction The LPCI-IIRO-8 is a Low-Profile PCI bus compatible card that provides isolated digital input and output interface for PCI-Bus computers. The card has eight optically-isolated digital inputs for AC or DC control signals and eight electromechanical relay outputs. LPCI-IIRO-8 occupies four consecutive 8-bit registers in I/O space. Features: • 8 optically-isolated, non-polarized CMOS compatible digital inputs accept +/-31volts DC or AC rms • 8 form C electro-mechanical relays switch up to 1 A each Inputs The LPCI-IIRO-8 provides eight optically-isolated inputs. These inputs can accept either AC or DC signals and are not polarity sensitive. Input signals are rectified by photocoupler diodes while unused power gets dissipated thru a 1.8k-ohm resistor in series. The inputs may be driven by either DC sources of 3 to 31 volts (rms) or AC sources at frequencies of 40 Hz to 10 KHz. Standard 12/24 AC control transformer outputs can be accepted as well. External resistors connected in series may be used to extend the input voltage range, however this will raise the input threshold range. Consult with factory for available modified input ranges. Each input circuit contains a switchable filter that has a 4.7 millisecond time constant. (Without filtering, the response is less then 40 microseconds) The filter must be selected for AC inputs in order to eliminate the on/off response to AC. The filter is also valuable for use with slow DC input signals in a noisy environment. The filter may be switched out for D C inputs in order to obtain faster response. Filters are individually selected by jumpers. The filters are switched into the circuit when the jumpers are installed in position FLT0 to FLT15. Ou tputs The board’s outputs are comprised of eight FORM C SPDT electro mechanical relays. These relays are all de-energized at power-on. 5 Manual LPCI-IIRO-8 Specification Isolated Inputs Number of inputs: Eight Type: Non-polarized, optically isolated from each other and from the computer (CMOS compatible) Voltage Range: 3 to 31 DC or AC Rms (40 to 10000 Hz) Isolation: 500V*(see note) channel-to-ground or channel-to channel Input Resistance: 1.8K ohms in series with opto coupler Filter Response Times: Rise Time = 4.7 mS / Fall Time = 4.7 mS Non-Filter Response Times: Rise Time = 10 uS / Fall Time = 30 uS *Notes on Isolation: Opto-Isolato rs and connectors are rated for at least 500V, but isolation voltage breakdowns will vary and is affected by factors like cabling, spacing of pins, spacing between traces on the PCB, humidity, dust and other environmental factors. This is a safety issue so a careful approach is required. For CE certification, isolation was specified at 40V AC and 60V DC. The design intention was to eliminate the influence of common mode. Use proper wirin g techniques to m inim ize voltage between channels and to ground. For example, when working with AC voltages do not connect the hot side of the line to an input. Tolerance of higher isolation voltage can be obtained on request by applying a conformal coating to the board. Relay Outputs Number of outputs: Eight SPDT form C Contact Type: Single crossbar; Ag with Au clad Rated Load AC: 0.5 A at 125 VAC (62.5 VA max.) Rated Load DC: 1A at 24 VDC (30 W max.) Max. Switching Voltage: 125 VAC, 60 VDC Max. Switching Current: 1 A Contact Resistance: 100 mS max. Contact Life: mech'l: 5 million operations min. Operating Time: 5 milliseconds max. Release Time: 5 milliseconds max. Power Required: 30 mA typical per Relay Energized Environmental: o Operating Temp: 0 - 70 C (Non-icing) Weight: 2.85 oz 6 Manual LPCI-IIRO-8 Figure 1-1: Block Diagram 7 Manual LPCI-IIRO-8 Chapter 2: Installation A printed Quick-Start Guide (QS G) is packed with the card for your convenience. If you’ve already performed the steps from the QSG, you may find this chapter to be redundant and may skip forward to begin developing your application. The software provided with this card is on CD and must be installed onto your hard disk prior to use. To do this, perform the following steps as appropriate for your operating system. Configure Card Options via Jumper Selection Before installing the card into your computer, carefully read Chapter 3: Option Selection of this manual, then configure the card according to your requirements. Our Windows based setup program can be used in conjunction with Chapter 3 to assist in configuring jumpers on the card, as well as provide additional descriptions for usage of the various card options. CD Software Installation The following instructions assume the CD-ROM drive is drive “D”. Please substitute the appropriate drive letter for your system as necessary. DOS 1. Place the CD into your CD-ROM drive. 2. Type d:K to change the active drive to the CD-ROM drive. 3. Type installK to run the install program. 4. Follow the on-screen prompts to install the software for this board. WINDOWS 1. Place the CD into your CD-ROM drive. 2. The system should autom atically run the install program. If the install program does not run prom ptly, click START | RUN and type d:install, click OK or press K . 3. Follow the on-screen prompts to install the software for this board. LINUX 1. Please refer to linux.htm on the CD-ROM for information on installing under linux. Caution! * ESD A single static discharge can damage your card and cause premature failure! Please follow all reasonable precautions to prevent a static discharge such as grounding yourself by touching any grounded surface prior to touching the card. 8 Manual LPCI-IIRO-8 Hardware Installation 1. Make sure to set switches and jumpers from either the Option Selection section of this manual or from the suggestions of SETUP.EXE. 2. Do not install card into the computer until the software has been fully installed. 3. Turn OFF computer power AND unplug AC power from the system. 4. Remove the computer cover. 5. Carefully install the card in an available 5V or 3.3V PCI expansion slot (you may need to remove a backplate first). 6. Inspect for proper fit of the card and tighten screws. Make sure that the card mounting bracket is properly screwed into place and that there is a positive chassis ground. 7. Install an I/O cable onto the card’s bracket mounted connector. 8. Replace the computer cover and turn ON the computer which should auto-detect the card (depending on the operating system) and automatically finish installing the drivers. 9. Run PCIfind.exe to complete installing the card into the registry (for Windows only) and to determine the assigned resources. 10. Run one of the provided sample programs that was copied to the newly created card directory (from the CD) to test and validate your installation. The base address assigned by BIOS or the operating system can change each time new hardware is installed into or removed from the computer. Please recheck PCIFind or Device Manager if the hardware con figu ration is changed. Software you write can automatically determine the base address of the card using a variety of methods depending on the operating system. In DOS, the PCI\SOURCE directory shows the BIOS calls used to determine the address and IRQ assigned to installed PCI devices. In Windows, the Windows sample programs demonstrate querying the registry entries (created by PCIFind and NTIOPCI.SYS during boot-up) to determine this same information. 9 Manual LPCI-IIRO-8 Chapter 3: Option Selection The only user configurable option available with this card are the input filters. If you install a jumper shorting block at any of the FLT0 through FLT7 jumper positions, that input channel (0-7, respectively) will have a filter applied. With the jumper shorting block removed the filter is also removed. Figure 3-1: Option Selection Map 10 Manual LPCI-IIRO-8 Chapter 4: Address Selection This card uses I/O addresses offset from the base address assigned by the PCI bus. The address spaces are defined in the Programming section of this manual. PCI architecture is Plug-and-Play. This means that the BIOS or Operating System determines the resources assigned to PCI cards rather than the user selecting these resources with switches or jumpers. As a result, you cannot set or change the card’s base address or IRQ level. You can only determine what the system has assigned. To determine the base address that has been assigned, run the PCIFind utility program. This utility will display a list of all the cards detected on the PCI bus, the addresses assigned to each function on each of the cards, and the respective IRQs. Alternatively, Windows systems can be queried to determine which resources were assigned. In these operating systems, you can use either PCIFind, or the Device Manager utility from the System Properties applet of the control panel. The card is installed in the Data Acquisition class of the Device Manager list. Selecting the card, clicking Properties, and then selecting the Resources Tab will display a list of the resources allocated to the card. The PCI bus supports 64K of I/O address space, so your card’s addresses may be located anywhere in the 0000h to FFFFh range. The card occupies eight consecutive 8 bit registers in the I/O address space. PCIFind uses the Vendor ID and Device ID to search for your card, then reads the base address and IRQ. If you want to determine the base address and IRQ without using PCIFind, use the following information: The Vendor ID code is 494F (ASCII for “I/O”) The Device ID code for the card is 0F01 An example of how to locate PCI card resources is provided in the PCI/SOURCE directory, under your installation directory. This code runs in DOC, and uses the PCI defined interrupt BIOS calls to query the PCI bus for card-specific information. You will need the Device ID and Vendor ID listed above to use this code. 11 Manual LPCI-IIRO-8 Chapter 5: Programming The base or starting address is assigned by the computer system during installation and will fall on a four bit boundary. LPCI-IIRO-8 read and write functions as follows: I/O Address Read Write Base +0 Read Relay Output Write Relay Output Base +1 Read Isolated Inputs Clear Interrupt Base +2 Enable IRQ Disable IRQ Base +3 IRQ Status Unused Digital Inputs Digital input states are read as a single byte from the port at Base Address +1. Each of the eight bits within the byte corresponds to a particular digital input. A "1" signifies that the input is energized and a "0" signifies that the input is de-energized. Bit Position D7 D6 D5 D4 D3 D2 D1 D0 Digital Input IP7 IP6 IP5 IP4 IP3 IP2 IP1 IP0 The card supports interrupts on change of state of digital inputs. Thus, it is not necessary to continuously poll inputs (by reading at base address +1) to detect any state change. To enable this interrupt capability, read at base address +2. To disable interrupts, write at base address +2. To clear an IRQ, write at base address +1. Relay Outputs At power-up, all relays are de-energized. The current state of the relays can be determined at any time by a read operation at the base address. The relay outputs are controlled by writing to the base address. Data are written to all eight relays as a single byte. Each bit within the byte controls a specific relay. A "1" energizes the corresponding relay and a "0" turns it off. D7 D6 D5 D4 D3 D2 D1 D0 Bit Position Relay Contr'd OP7 OP6 OP5 OP4 OP3 OP2 OP1 OP0 For example, if bit D5 is turned on by writing hex 20 to the base address the relay that controls OP5 is energized (closing the associated normally-open contacts). All other relays would be de-energized and their normally-closed contacts would be closed. 12 Manual LPCI-IIRO-8 Base+3 IRQ Status Bit Position D7 D6 D5 D4 D3 D2 D1 D0 Function IRQ IRQ Occurred Enable Reading Base+3 provides status bits associated with IRQ operations. Bit 0: a high bit indicates an IRQ has occurred since you last read this register. Bit 1: a high bit indicates the IRQs are enabled (by writing to base+2). 13 Manual LPCI-IIRO-8 Chapter 6: Connector Pin Assignments Pin # Signal Name Pin # Signal Name 1 Ground 23 Relay 7 NO 2 Input 7 B 24 Relay 6 NO 3 Input 5 A 25 Relay 5 NO 4 Input 4 B 26 Relay 4 NO 5 Input 2 A 27 Relay 3 NO 6 Input 1 B 28 Relay 2 NO 7 No Connect 29 Relay 1 NO Relay 7 8 30 Relay 0 NO Common Relay 6 9 31 Input 7 A Common Relay 5 10 32 Input 6 B Common Relay 4 11 33 Input 4 A Common Relay 3 12 34 Input 3 B Common Relay 2 13 35 Input 1 A Common Relay 1 14 36 Input 0 B Common Relay 0 15 37 Relay 7 NC Common 16 No Connect 38 Relay 6 NC 17 Input 6 A 39 Relay 5 NC 18 Input 5 B 40 Relay 4 NC 19 Input 3 A 41 Relay 3 NC 20 Input 2 B 42 Relay 2 NC 21 Input 0 A 43 Relay 1 NC 22 No Connect 44 Relay 0 NC Table 6-1: Connector Pin Assignments 14 Manual LPCI-IIRO-8 Customer Comments If you experience any problems with this manual or just want to give us some feedback, please email us at: tech@portwell.com. Please detail any errors you find and include your mailing address so that we can send you any manual updates. 15 Manual LPCI-IIRO-8

Frequently asked questions

Why choose IPC Station?

What is IPC Station' warranty policy for the LPCI-IIRO-8?

What carriers does IPC Station use to ship parts?

Does IPC Station sell to international (non-USA) customers?

What methods of payment does IPC Station accept?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Related Products

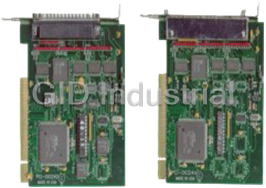

Parallel digital input/output cards designed for use in PCI-Bus computers. The same printed circuit ...

24-bit parallel, digital input/output cards designed for use in PCI-Bus computers. The difference be...

24-bit parallel, digital input/output cards designed for use in PCI-Bus computers. PCI-DIO24H are vi...

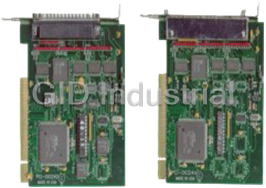

24-bit parallel digital input/output cards designed for use in PCI-Bus computers. The card is 6.9 in...

48-bit parallel digital input/output cards designed for use in PCI-Bus computers. The card is 6.9 in...

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods